Cat gas engine configuration

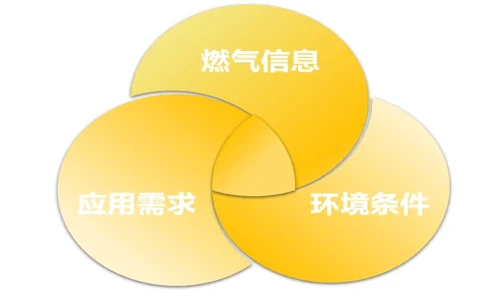

“Where should I start when selecting a gas generator set?” “What is the use of gas information and environmental conditions in selecting a unit?” First of all, you need to understand the following three types of information when configuring a gas unit, and each type has several factors that need to be considered.

· Gas information is used to determine the type and power range of the Cat unit;

· Environmental conditions mainly refer to geographical factors, which will affect the output power of the unit and the selection of additional configurations;

· Project application requirements are mainly aimed at different configurations of auxiliary equipment caused by differences in project application areas and application scenarios.

Gas Information

1. Gas types

Gas types include the following categories:

2. Engine application

Caterpillar classifies gas engines according to different gas types:

What the gas information contains

1. Gas pressure

Gas pressure size and fluctuation range: Cat gas engine gas pressure 20-200mbar. Different engine mixers are configured for different gas pressures. Fluctuation range: ≤±10%. If the gas fluctuation range is greater than this requirement, please install a pressure regulating valve in front of the engine gas intake valve group (Gas train), or add a gas storage tank in the project design to stabilize the pressure fluctuation.2. Gas volume and composition

The composition of the gas determines the methane value and low calorific value of the gas, and the methane value and low calorific value of the gas will determine the application of the engine. For biogas generator sets, all biogas needs to be used as much as possible. At this time, the selection of our unit power mainly depends on the flow rate and composition of the biogas. We will match the best model and quantity according to the overall energy utilization of the customer’s factory.3. Concentration of harmful substances

If the gas contains harmful substances and its concentration exceeds a certain range, it must be treated before it can be used as engine fuel. Harmful substances such as hydrogen sulfide, halides, ammonia, etc. Caterpillar specifically lists the allowable values for various hazardous substances:Environmental factors

Environmental conditions mainly refer to geographical factors, which will affect the output power of the unit and the selection of additional configurations.

Environmental factors include the following categories: